While Huntington Ingalls Industries’ Newport News Shipbuilding division has been innovating in its field for the last 132 years, the company stands today at the precipice of a new era. The state’s largest industrial employer, with more than 22,000 employees, is focusing on enhancing its digital infrastructure. In June 2018, the company announced in plans to invest nearly $1 billion in its facilities and technology infrastructure, as well as employee training necessary to lead a digital upgrade in shipbuilding processes.

The integrated Digital Shipbuilding project aims to empower the company’s workforce through improved ease of access to secure information, with new tools that include 3D work instructions as well as the augmented reality, modeling, simulation, and laser-scanning technologies that are being proven in other market segments to help speed even the most complex designs more quickly and accurately into production.

Training and hiring necessary to support this transformation is being supported by a unique partnership with the Governor’s office and assistance from state agencies. The plan is not only to create a more digitally sophisticated workforce, but also to amp up manpower across its 550 acres to fulfill its contract to build components for new Columbia-class submarines. Newport News Shipbuilding intends to hire nearly 7,000 people, with creation of 2,000 new jobs, over the next five years.

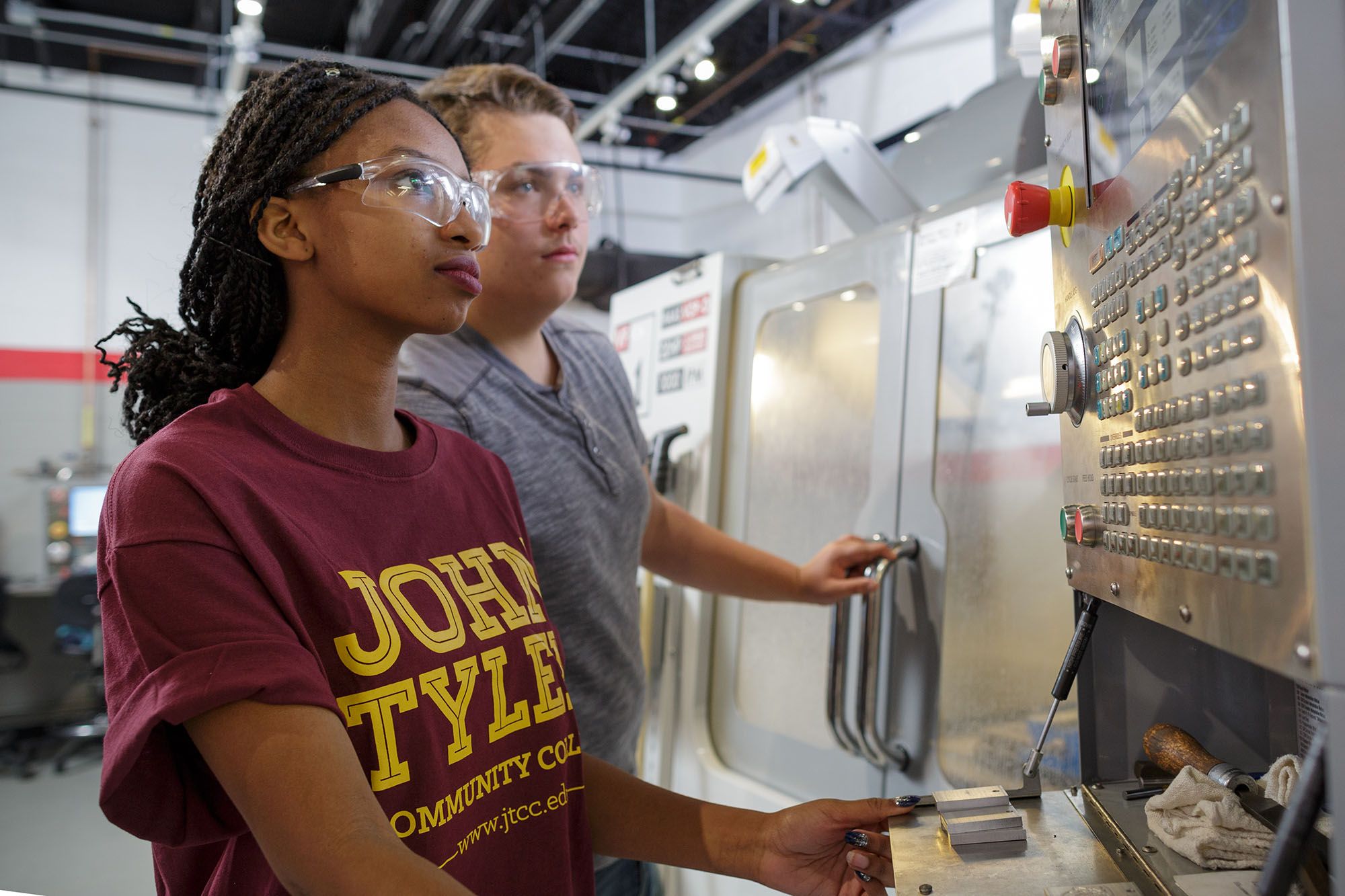

The state has provided funding for the organization’s robust maritime prehire program that is operated through local community colleges.

In addition to this program, the shipbuilder stands to benefit from a Growth and Opportunity for Virginia (GO Virginia) grant and state funding to Old Dominion University, which will develop a curriculum centered on the skills needed to succeed in digital shipbuilding.

“Old Dominion University is developing curricula for engineers, IT professionals and trades workers to ensure they’re prepared to incorporate new technologies in shipbuilding and that they’ll be able to constantly innovate and change as the industry is disrupted,” Rob Hogan, vice president of manufacturing for Newport News Shipbuilding, explained.

Maintaining Infrastructure That Connects Businesses

While Virginia’s workforce stands out to manufacturers, there’s another reason the Commonwealth attracts manufacturers in so many fields. As Beckman put it, facilities are “conveniently located near major interstates, which makes it easy to move raw materials and finished products into and out of the facility.”

VMA’s Vision document highlights infrastructure as an important component in driving manufacturing growth. While the workforce development available through Virginia’s expansive network of four-year and community colleges and technical training programs may serve as the heart of a diverse range of manufacturing operations, consider the state infrastructure the venous system connecting manufacturers to raw materials and products to end-users around the world.

When it’s time to send products out to market, the state’s international gateways, including The Port of Virginia and Washington Dulles International Airport, simplify the process of getting products not only across the country but around the world. These gateways provide the necessary logistical access to ship Virginia products to international markets, and with that access comes the international service industry to facilitate exports, such as freight forwarders, custom house brokers, attorneys, bankers, etc.

However, Hogan pointed out that one of the reasons the state is an ideal location for manufacturers isn’t just the ease of getting products out, but the ease of bringing in materials. “There are lots of options to bring in materials through transportation networks, including rail, water, and road,” he said.

Small Business Success

While easy proximity to international markets noticeably attracts large manufacturers, part of the Commonwealth’s strength in manufacturing lies in its diversity. VMA notes that 74% of the state’s manufacturers have fewer than 25 employees.

Small companies not only supply components, research, and technology that their larger counterparts can put to use — with the right support, they can drive the innovation that will make them tomorrow’s large employers.